C-panel wall construction

-

Development of C-panel wall construction

-

C-panel wall construction was developed by technical knowhow accumulated for long years by TOAMI.

Recently, needs for buildings are diversified in the form of energy saving and higher performance. This construction method is developed from technical themes of improvements of heat resistance, sound insulation and fire resistance of exterior wall while labor saving is realized. With this method, problems of conventional PC curtain wall such as inefficient workability and inconvenient degree of freedom of designing are eliminated. This method also satisfies the proposition of environmental preservation. In this sense, this method may be referred appropriately to [Hybrid wall] produced by the era.

Since brought to the market, C-panel wall was employed in the construction of assembly house of Okushiri-cho, exterior wall of Kobe waterfront and La Villa Española de Shima, and partition wall of students' hall of Osaka University and highly appreciated. Unique characteristics of this panel that competitors are incapable of imitating are applied to various architectures.

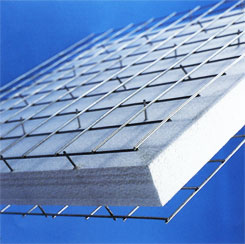

- C-panel

- Wire mesh welding process for C-panel

- Final assembly process (Portion)

- Final assembly process (Portion)

- Final assembly process

- C-panel before shipment

-

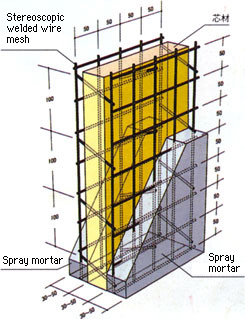

C-panel construction

-

When inner wall or outer wall is mounted, specially blended cement mortar is sprayed on the surface of C-panel and the surface is finished with a trowel. We developed this technique in 1988 by joint development with leading general contractor.

Although its strength, durability and fire resistance are comparable to those developed by conventional RC wall, heat insulating properties are remarkably superior to those of RC wall having identical thickness.

Since no formwork is necessary, problems associated with the shortage of mold workers are eliminated and conventional costs are reduced thereby improving the economy. At the same time, resource protection of tropical timbers used for the mold form is attained.

Further, C-panel is as light as 5 kg/m2 and large machinery is not required at installation thereby contributing to simplification of the construction.

In addition, a variety of surface finishing and curvatures are created easily by pasting tiles on the finished concrete wall. This expands design options.

As for core material, expanded polystyrene, paper core and glass wool are mentioned which are selected properly depending on the intended use.